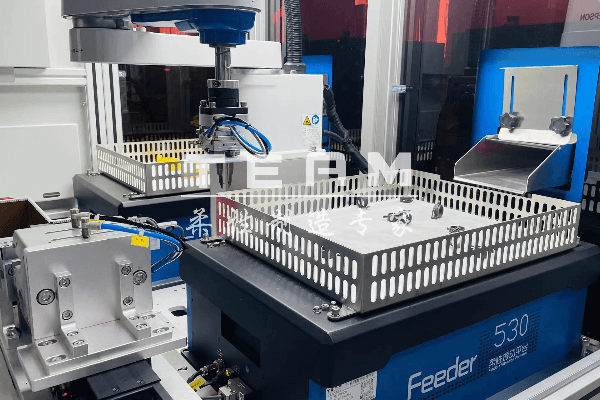

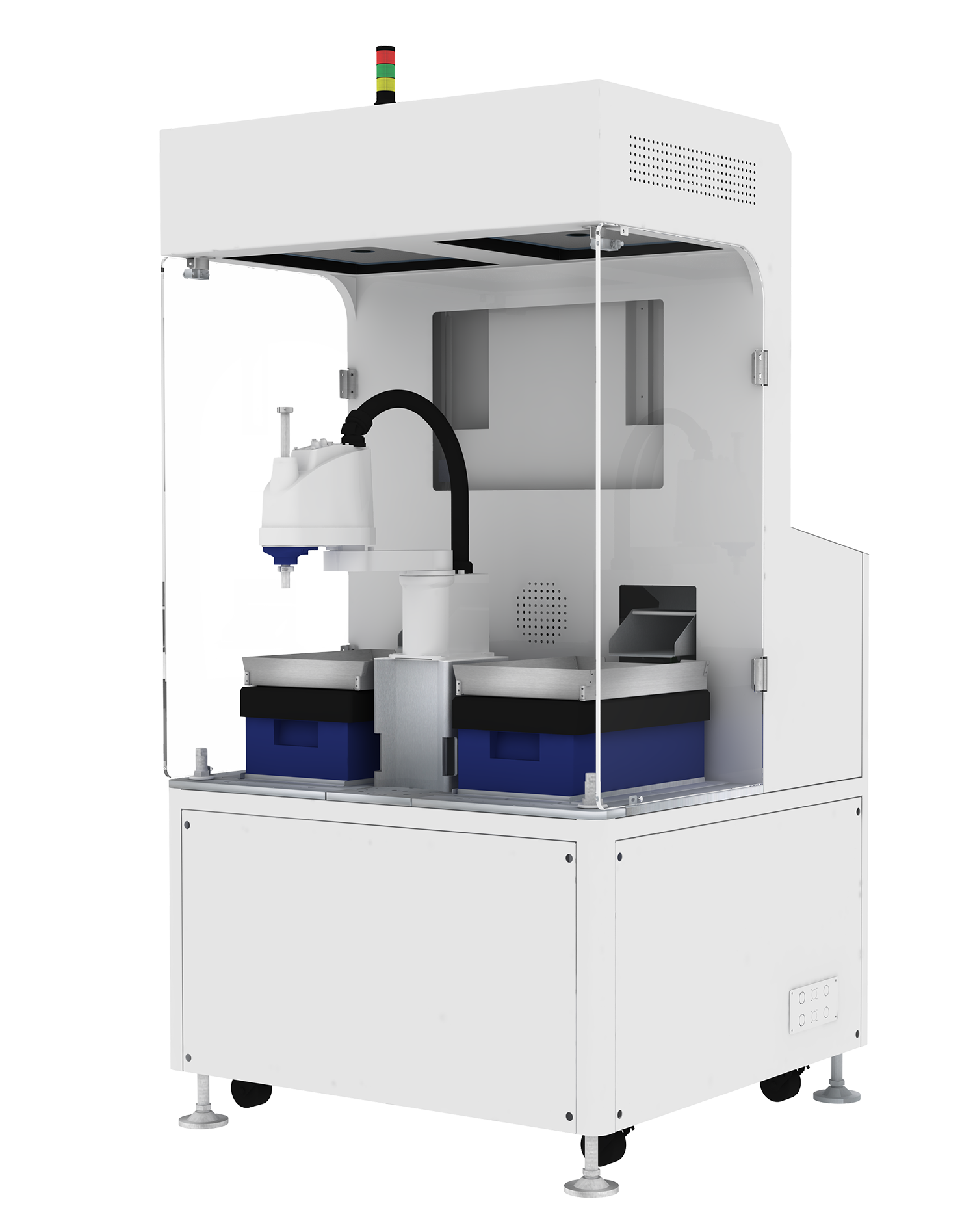

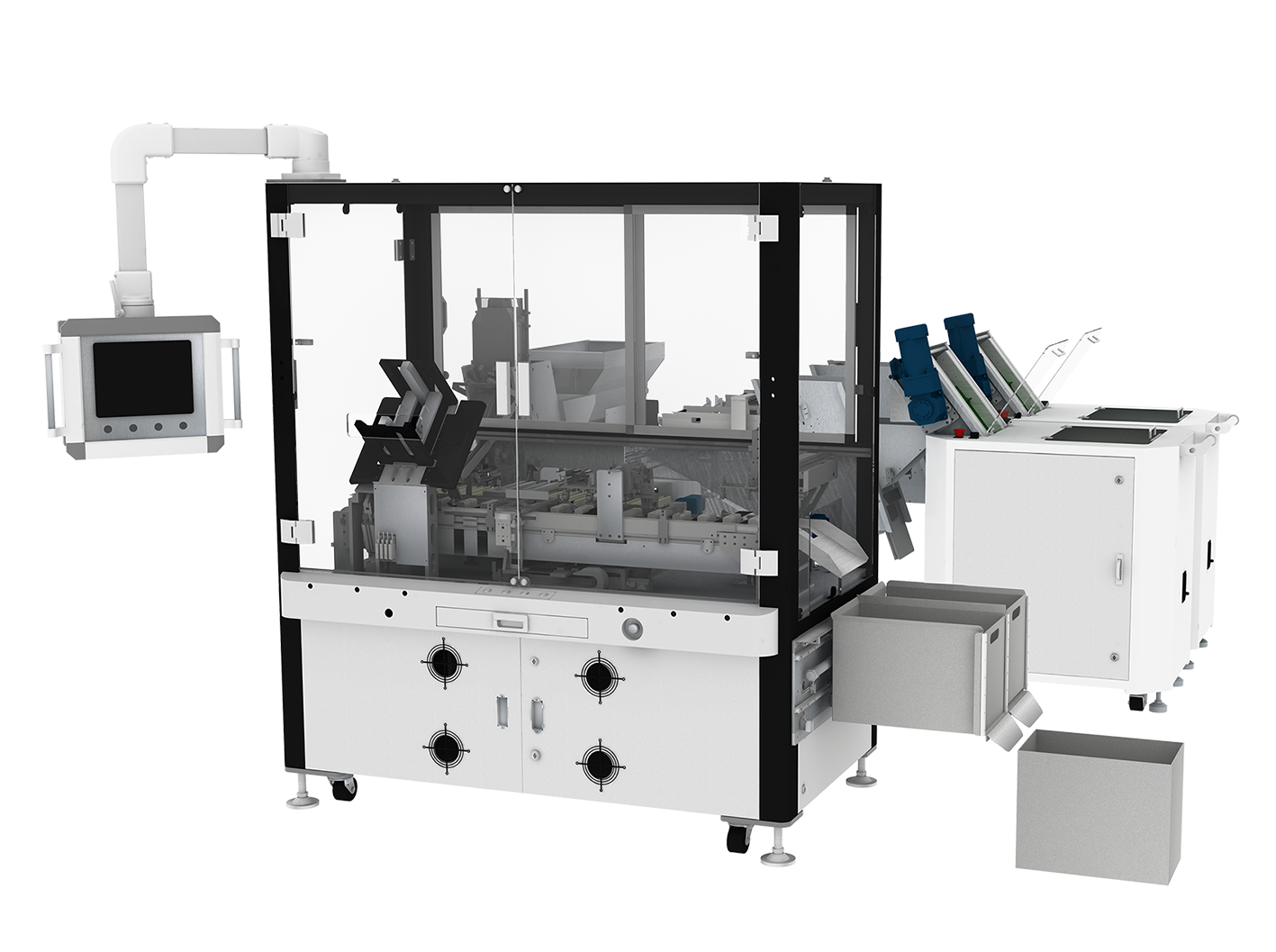

Visual technology plays a crucial role in automated feeding systems, as these systems rely on visual recognition and material identification to complete the feeding process. Various factors can affect the accuracy of visual systems, including camera precision, image processing, recognition algorithms, and optical distortion.

Do You Think What We See is What We Get?

Not exactly. The true image captured by our eyes may not look the same as what we perceive.

Our brain corrects the image we see, making it appear normal. The primary cause of this visual difference is optical distortion, specifically image aberrations.

1. What is Visual Distortion?

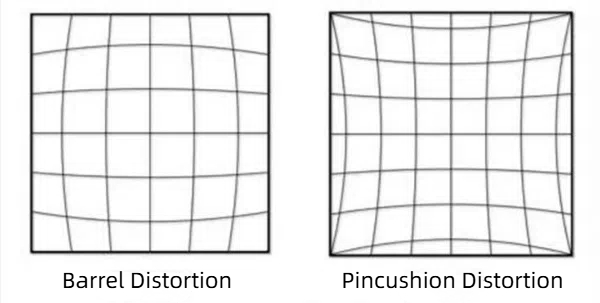

Visual distortion occurs when straight lines in the object’s plane of view appear curved after being imaged by an optical system. This error is called "distortion." In simpler terms, camera distortion can cause an image to appear “stretched” or “twisted,” leading to irregularities such as "crooked" or “misaligned” objects.

In everyday life, optical distortion has practical applications. For example, convex lenses at street corners or car side mirrors use distortion to expand the field of view.

2. Types of Visual Distortion

In a visual-based automated feeding system, mathematical formulas are used to convert world coordinates into pixel coordinates. However, like the human eye, cameras inevitably experience distortion during the imaging process.

Barrel Distortion

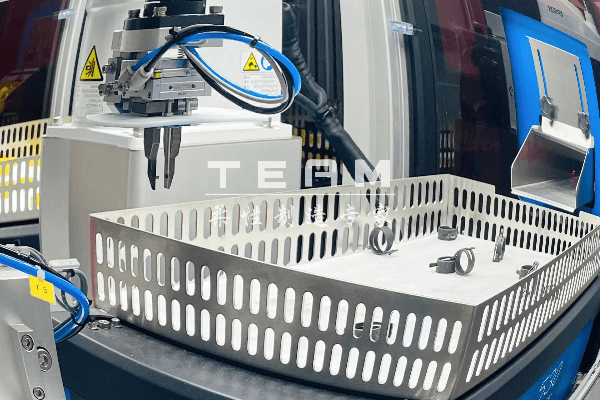

For example, when two materials—one taller and one shorter—are imaged by a camera, the higher material will appear more distorted. This results in barrel distortion, where objects appear stretched or bulging in the middle.

Pincushion Distortion

When the same materials are moved from a smaller to a larger tray, the camera’s expanded field of view increases the distortion. This results in pincushion distortion, where the image appears to "squeeze" inward at the edges.

How Automated Feeding Systems Address Visual Distortion

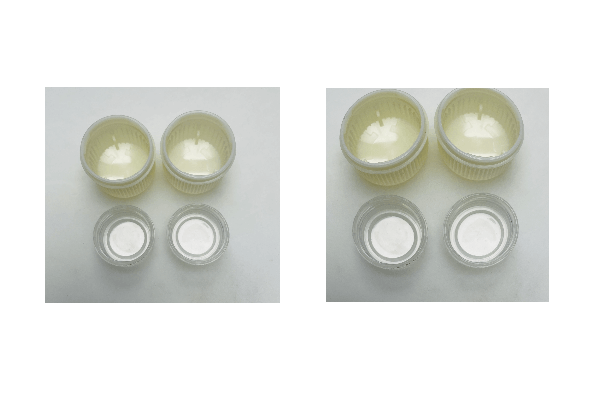

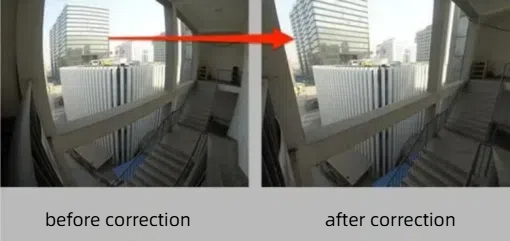

In automated feeding systems, visual recognition is crucial for accurately identifying and grasping materials. To ensure precision, it’s essential to correct visual distortions, a process known as distortion correction.

Distortion correction is typically achieved through camera calibration, which involves adjusting both external and internal camera parameters. By calculating eight parameters and applying specific algorithms, each misaligned pixel can be corrected, effectively eliminating camera distortion.

Home

Home Products

Products Telephone

Telephone Message

Message