Quick Integration

Connect any number and types of hardware devices by dragging and dropping, and quickly establish a communication network for hardware in the automation system

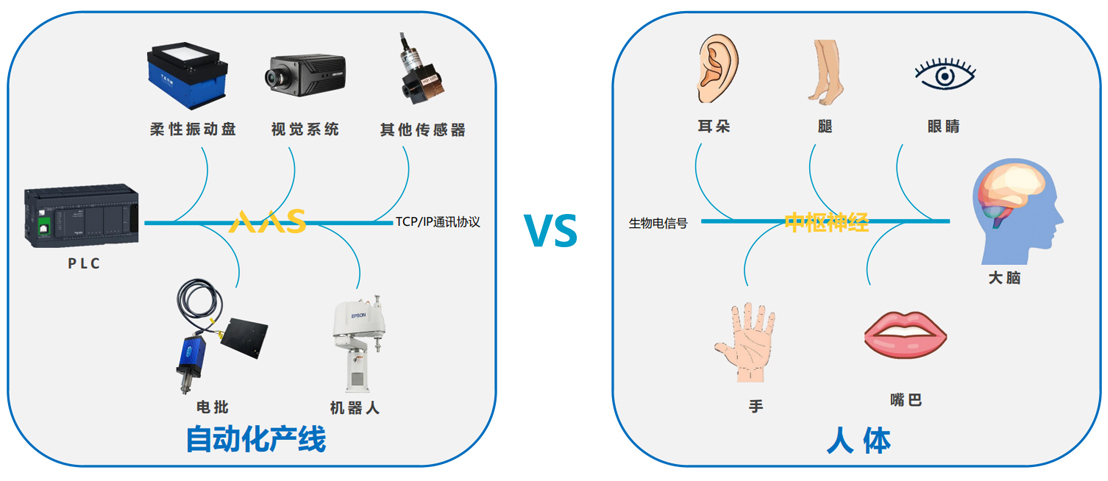

Automatic Assemble Software

Connect any number and types of hardware devices by dragging and dropping, and quickly establish a communication network for hardware in the automation system

Support custom device parameter variables, flexible modification of various parameters can be completed without modifying the code

Calibration process package, complete the calibration of robot motion mechanism and vision system with one click

80% automation applies standardized packaging to realize one-click calling of common vision, feeder, and robot operation processes

| Application Scenario | Traditional Automation Integration | Integration using AAS |

| Robot debugging | 5 years of experience in senior software engineers, robot debugging engineers to complete the cooperation | √A 3-month-experienced robot debugger can use AAS independently |

| Automated Line Design | Senior PLC electrical engineer + robot programming + 5 years experience senior software engineer took about 2 weeks to complete | √An experienced engineer uses AAS independently Takes 2-3 days to complete |

| Need to upgrade the production line | Relevant engineers are required to modify the source code to cooperate Production line upgrade | √Directly use AAS to modify relevant parameters Done, no need to change the code |

Integrate PLC, visual algorithm, feeder, robot and other systems to quickly build an integrated automation application center

Low-code modular design, complete project design by dragging and dropping, modifying parameters, one-click calling, etc., easy to learn

There is no need to modify the code to reconnect the device, and the production line system can be upgraded by modifying parameters and dragging and dropping, which is as flexible as building blocks

There is no limit to the type and quantity of connected devices, and it is compatible with different brands of robots, feeders, etc.

Quality Management System

National High-tech Enterprise

50+Patent

Specialized and new

Suzhou Gazelle Enterprise