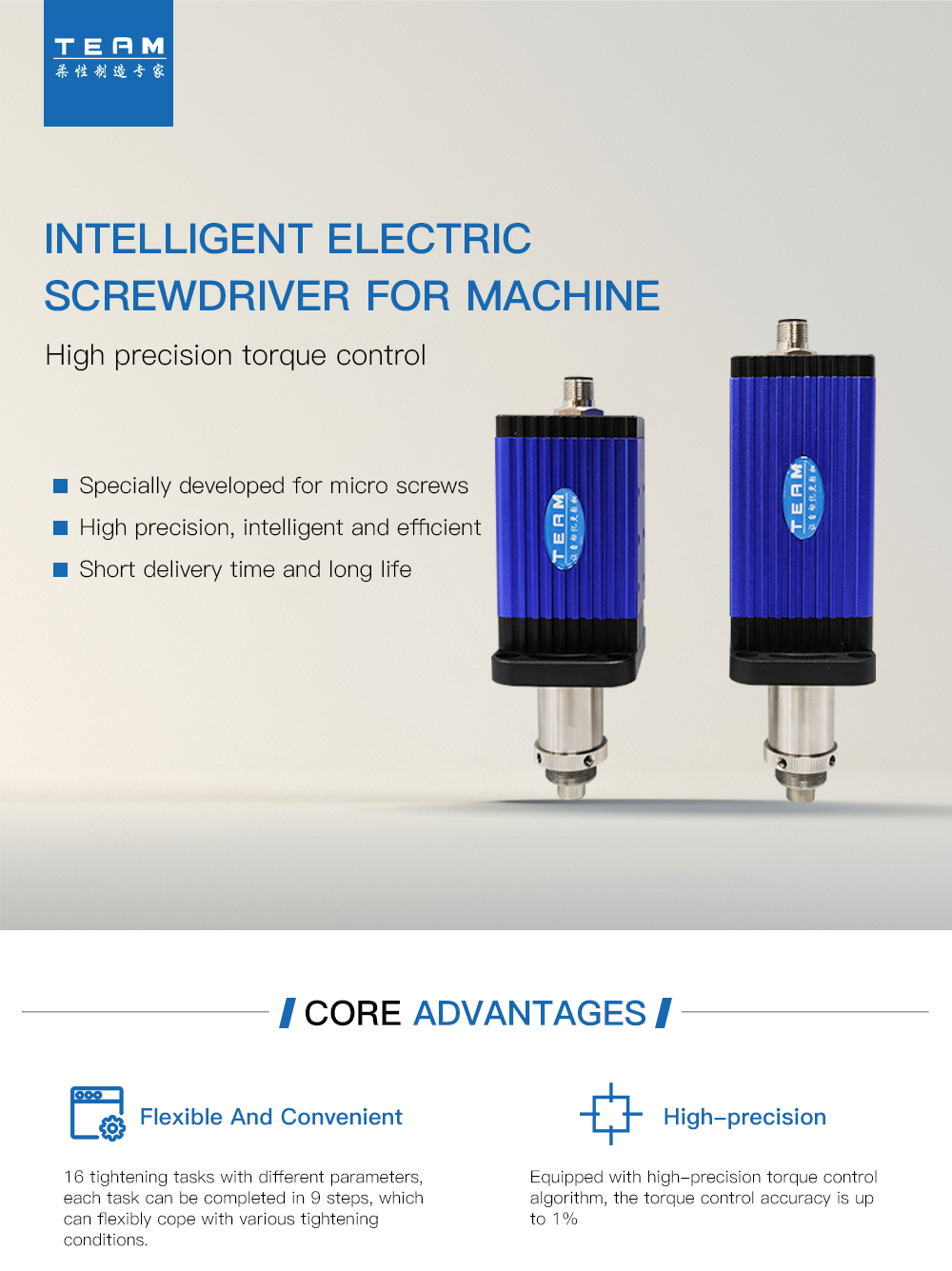

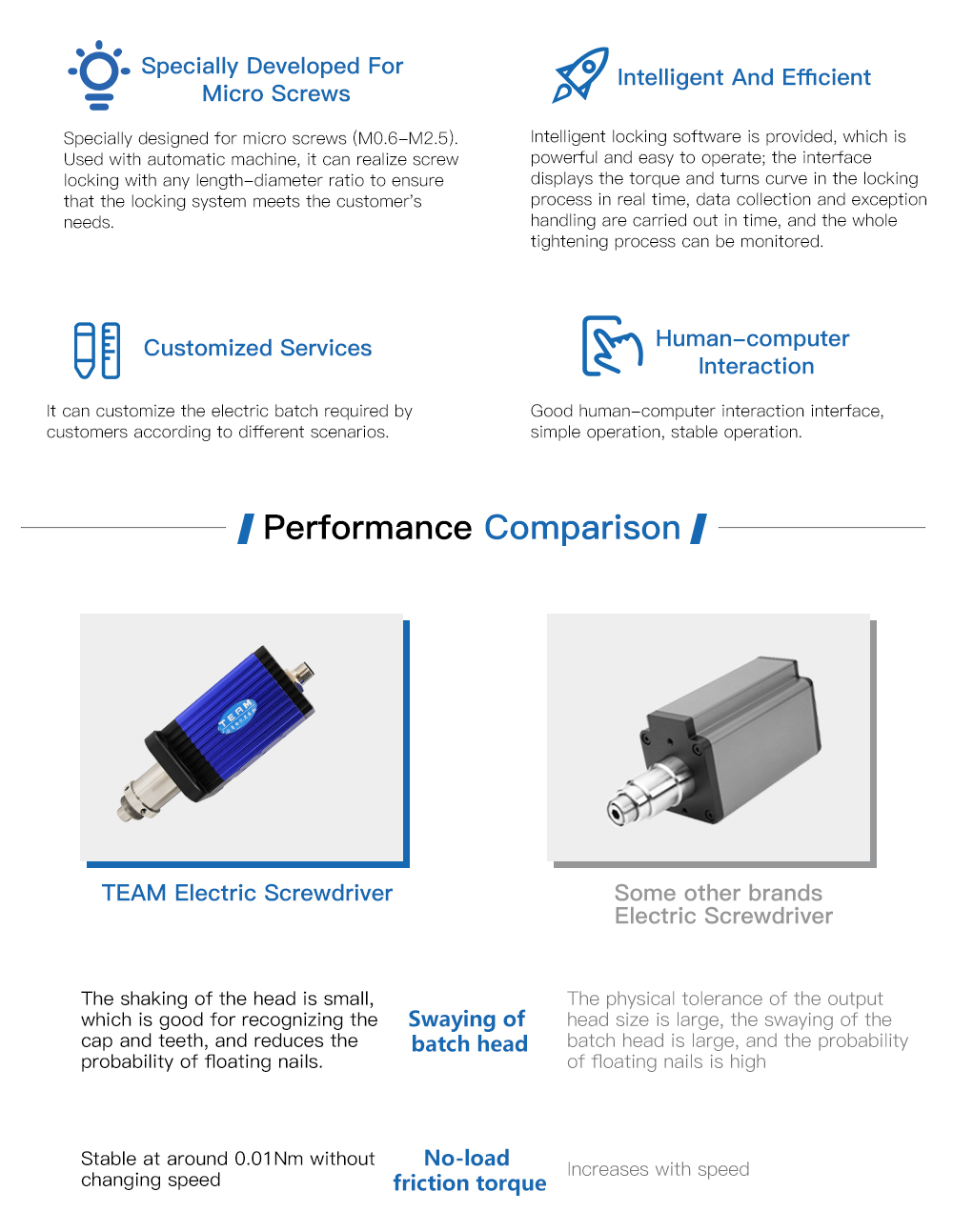

Focus on microfabricationSpecially designed and developed for M0.6-M2.5 screws, born for more precision

Longer lifeMaintenance-free after commissioning, after tens of thousands of fatigue tests, durable

Higher precisionEquipped with high-precision torque control algorithm, the torque control accuracy reaches 1%

Process controlThe supporting software interface displays the torque and turn curves of the locking process in real time, and the data collection and exception handling can be carried out in real time, and the whole process of tightening can be monitored

Automatic monitoringProvide monitoring function with locking torque, number of turns, screw slippage, floating height, tilt, etc., and automatically determine the locking status to give a signal.

Wide range of applications16 different parameters of the tightening task, each task can be completed in 9 steps, can be flexible to deal with a variety of tightening conditions

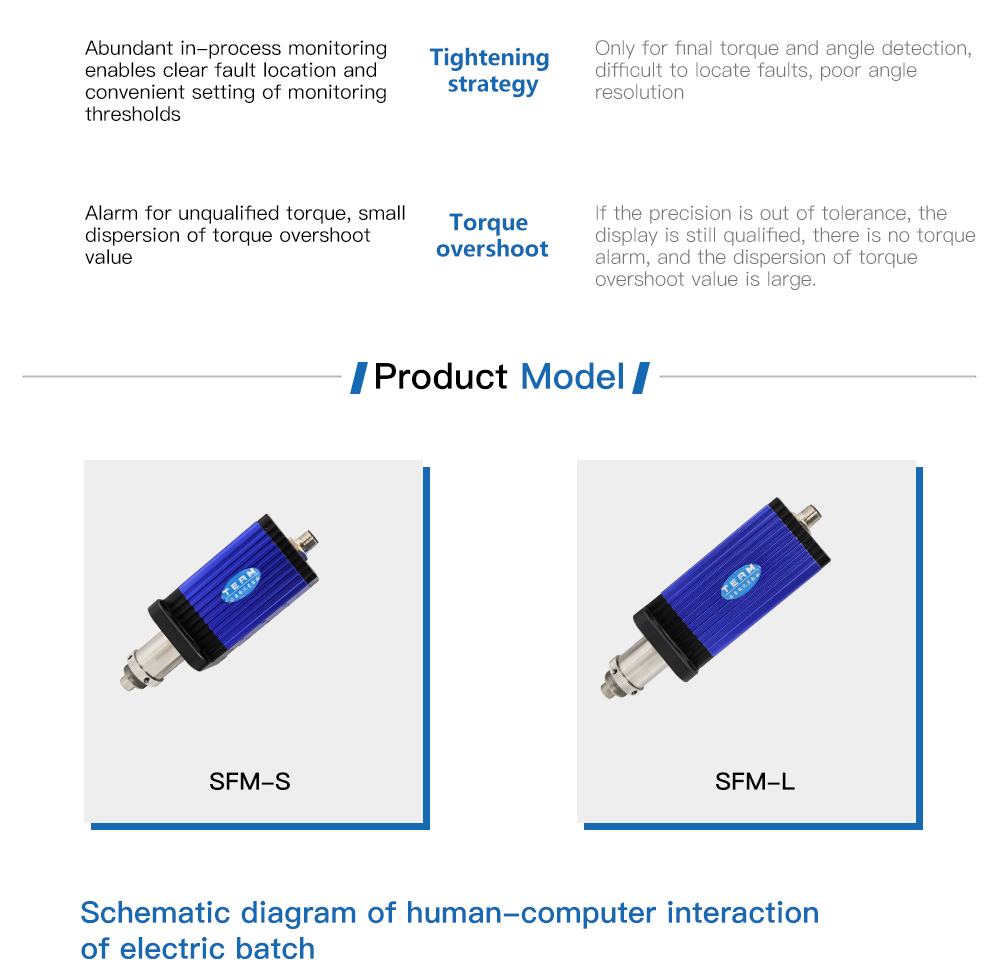

| Specification | SFM - S | SFM - L |

| Screw Size | M0.6~M1.6 | M1.2~M2.5 |

| Target torque setting | 0.1 kgf.cm ~ 0.7 kgf.cm | 0.3 kgf.cm ~ 1.4 kgf.cm |

| Dimensions | 51.6*40.5*86mm | 51.6*40.5*106mm |

| Operating mode | Laps / Duration / Step | |

| Rotating speed | 3600 rpm | |

| Motor control method | Closed loop | |

| Electric batch control mode | PC(TEAMElectric License Assistant) | |

| Rotation mode | CW/CCW | |

| Power Supplies / Motors | DC24V(3A)/ Stepper motor | |

| Precision | ±0.01 kgf.cm | |

| Communication method | Modbus TCP | |

| Number of programs / number of steps | 16 / 9 | |

Quality Management System

National High-tech Enterprise

50+Patent

Specialized and new

Suzhou Gazelle Enterprise