In flexible feeding systems, some materials can be fed at a rate of one piece per second, while others take three or four seconds per piece. What factors influence these differences in feeding speeds?

The truth is that feeding speed is less about the equipment itself and more about the characteristics of the material and the requirements of subsequent processes.

1. Differences in Pick-and-Place Precision

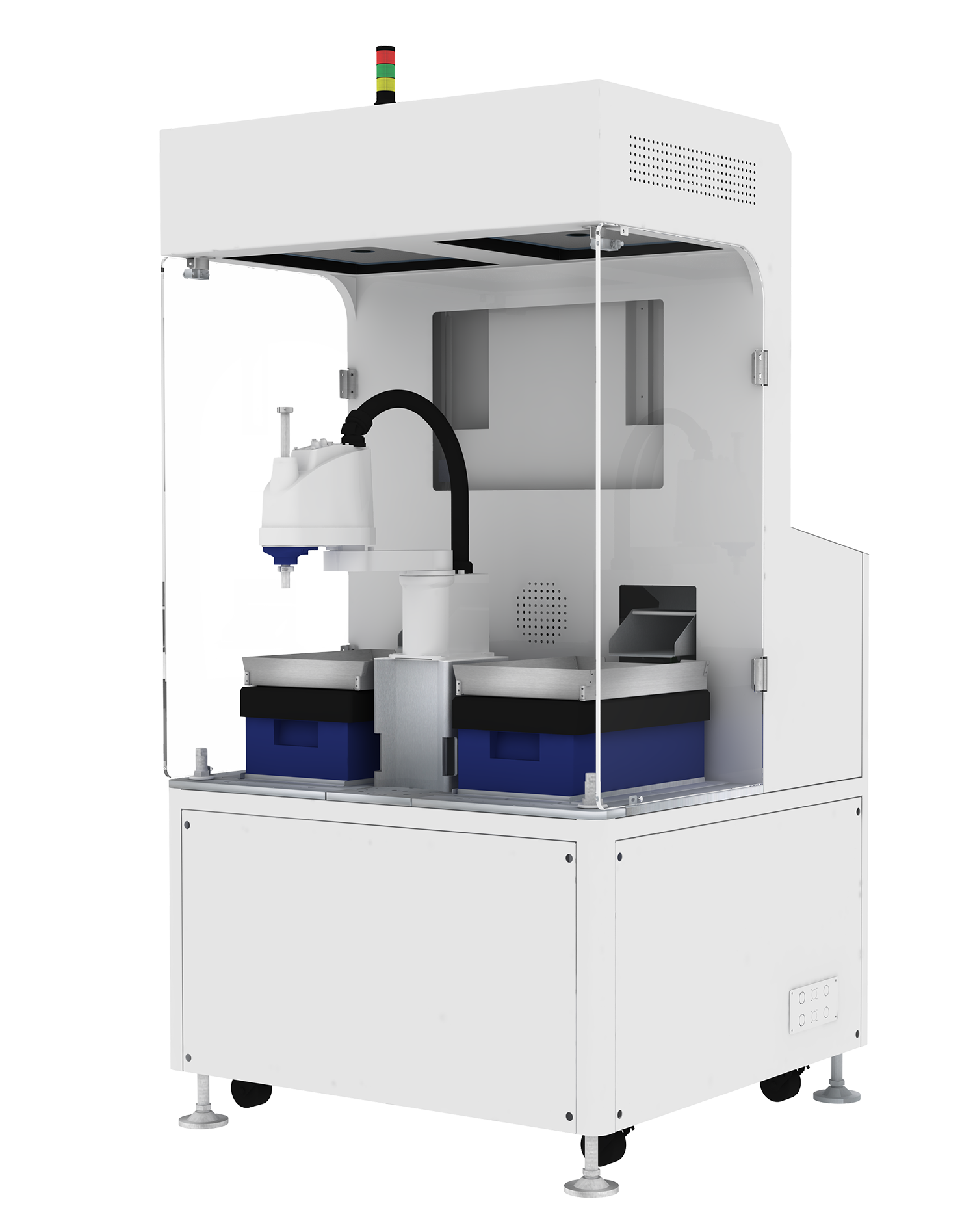

Pick-and-place precision is one of the most critical factors affecting feeding speed. For instance, flexible feeding systems used for tray placement with low precision requirements only need two simple steps: pick and place. These systems can operate at high speed.

However, for assembly feeding—where different parts need to be precisely aligned for assembly—precision becomes crucial. The added complexity of ensuring proper alignment naturally slows down the feeding speed.

The purpose of feeding significantly affects the required cycle time.

2. Material Shape and Characteristics

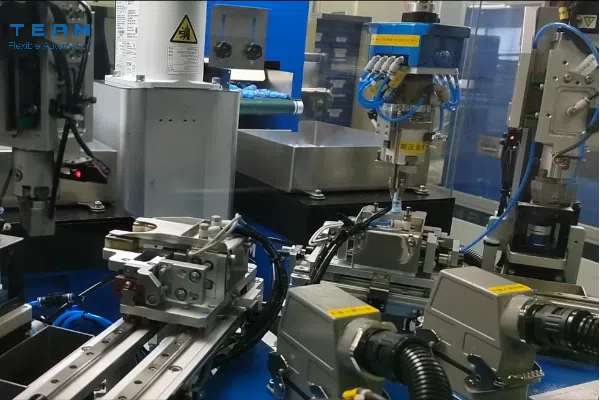

The shape and properties of materials greatly influence feeding speed. Take, for example, a perfectly shaped round metal disc—it is much easier to feed compared to a deformable, irregularly shaped spring.

Standard shapes like round metal discs are compatible with multiple feeding methods and are less prone to issues.

Irregular springs, on the other hand, pose unique challenges due to their shape, tendency to deform, and risk of entanglement. Feeding these materials requires extra time to ensure they are gripped securely, placed stably, and remain undamaged.

Materials that can be handled using suction-based feeding systems often have faster feeding speeds. Suction systems are less affected by surrounding interference compared to clamping methods. Conversely, materials that require clamping and are surrounded by other components may experience slower feeding speeds due to increased difficulty in precise gripping.

Challenging materials like transparent parts, irregularly shaped components, flexible items (e.g., cables or wires), or soft, easily deformable materials require careful handling. These materials highlight the importance of understanding their specific characteristics rather than solely prioritizing speed.

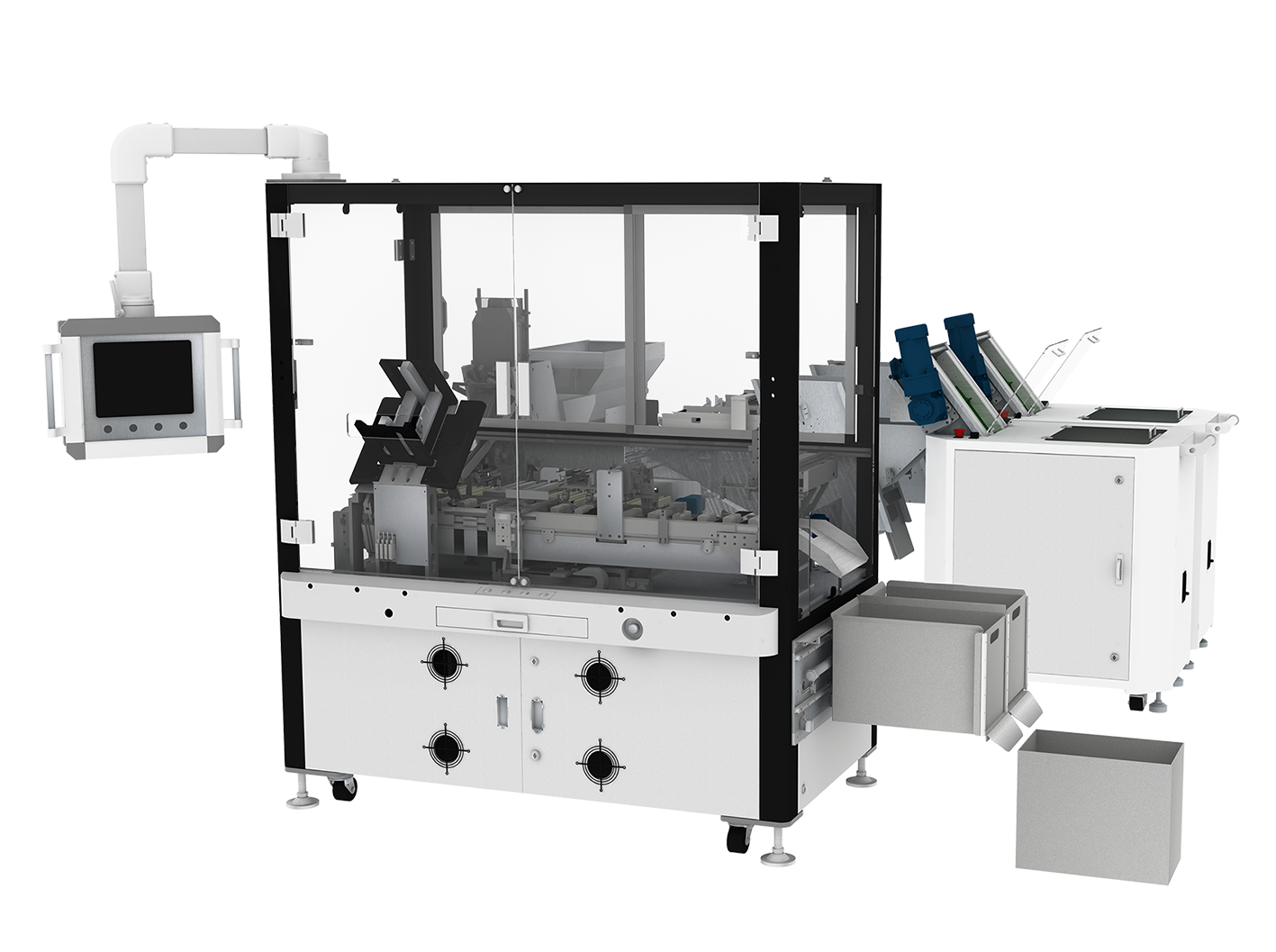

3. Feeding Orientation Requirements

Material orientation requirements can also impact feeding speed.Questions such as these must be addressed:

Does the system need to differentiate between the front and back sides?

Are there specific orientation requirements during gripping? Is achieving the desired placement orientation straightforward? While humans can quickly adjust for these requirements using judgment and dexterity, machines rely on precise programming to execute every motion. The more stringent the orientation requirements, the more complex the programming.

For some materials, achieving the desired orientation may even require additional mechanisms like flipping devices or secondary positioning systems, further slowing down feeding speeds.Additionally, if the material’s gripping position affects its stability—such as maintaining its center of gravity—slowing down the feeding speed can help preserve accuracy. Rapid movement in such cases may lead to errors or a loss of precision.

Conclusion

The differences in feeding speeds are influenced by factors such as pick-and-place precision, material shape, and orientation requirements. However, these are only part of the story. Many other variables—such as material weight, surface properties, and the overall complexity of downstream processes—also play a role.

When it comes to flexible feeding, it's essential to evaluate the specific needs of each material and application rather than striving for speed alone. By tailoring the feeding process to material characteristics and application demands, companies can achieve both efficiency and precision in automation.

Home

Home Products

Products Telephone

Telephone Message

Message