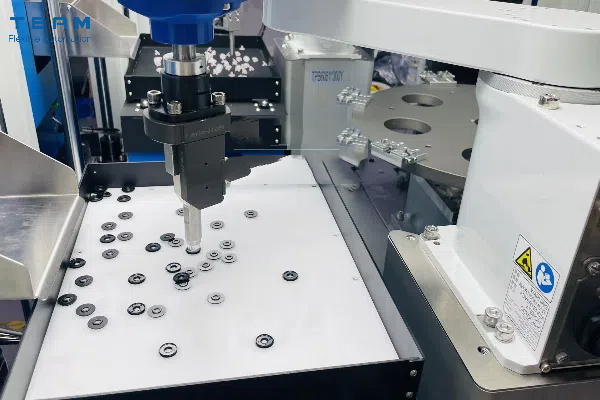

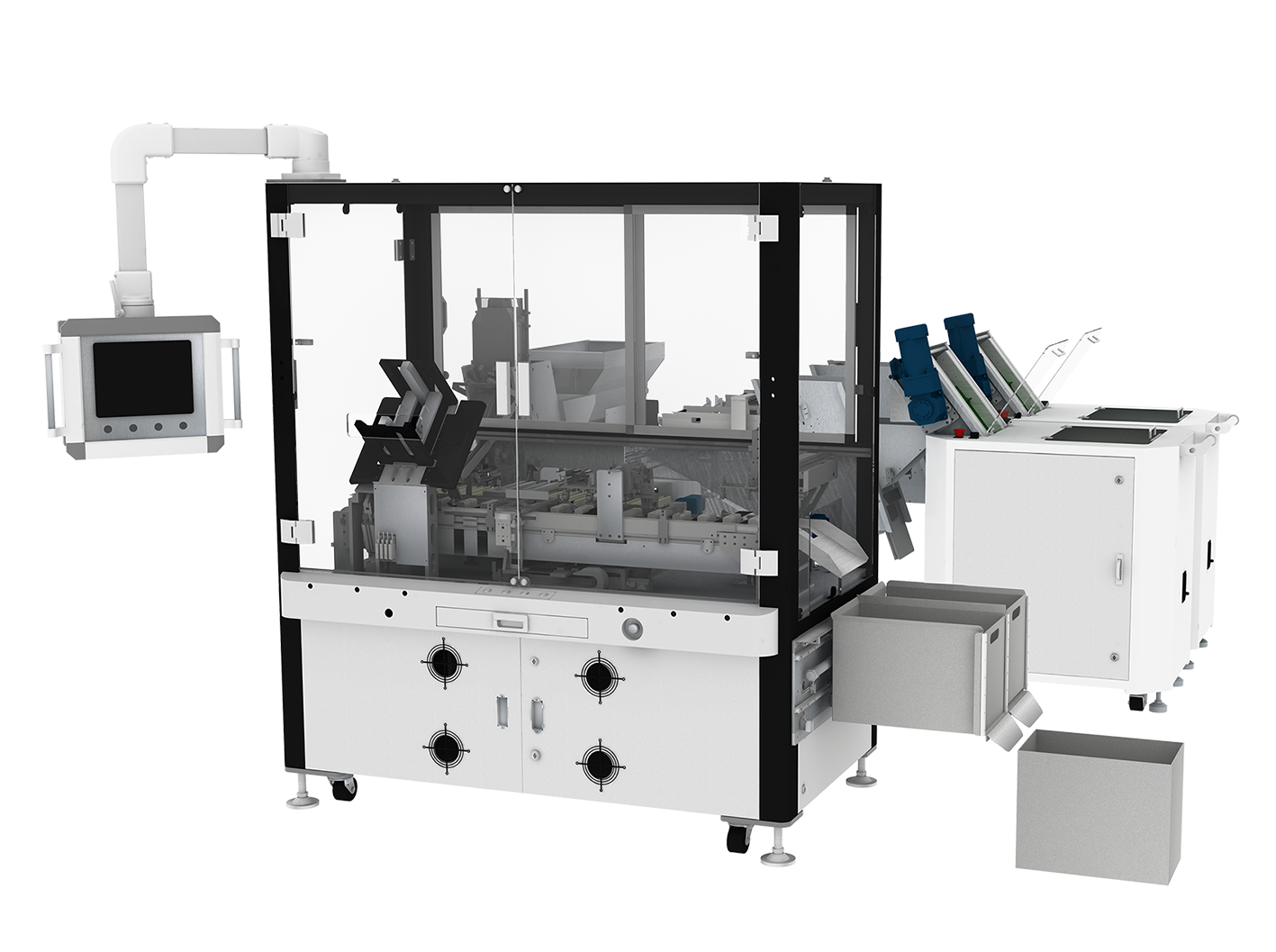

The automation industry involves an extensive variety of components that require feeding, yet real-world operations often encounter challenges from multiple variables. Relying solely on experience without conducting feasibility tests is akin to setting yourself up for failure.

Take, for instance, micro springs or irregularly shaped springs. These components have curved shapes and large gaps, making them prone to jamming or sticking if not handled carefully. While experience suggests using vibration feeding techniques—be it bowl or flexible vibrations—the choice of method largely depends on the specific properties of the spring material. Without actual testing, such decisions may lead to issues during implementation.

Fine-Tuning Vision Systems

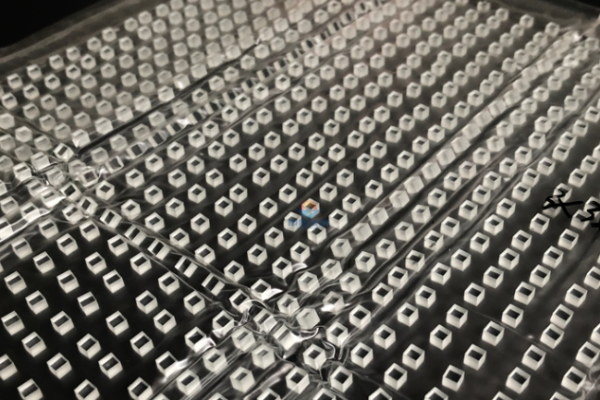

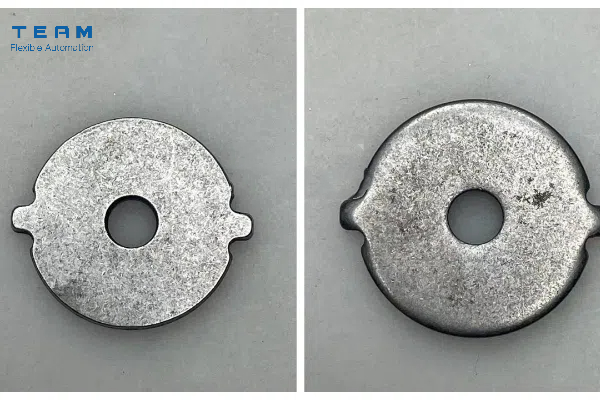

Vision systems also demand continuous adjustments to accommodate different materials. Parameters like lighting, background, and lens settings must all be optimized. For example, transparent materials are difficult to identify against a white background. Switching to a black surface can significantly enhance recognition accuracy. Similarly, components with minimal differences between concave and convex surfaces may require specialized lighting techniques and extensive fine-tuning to capture distinguishing features for precise picking.

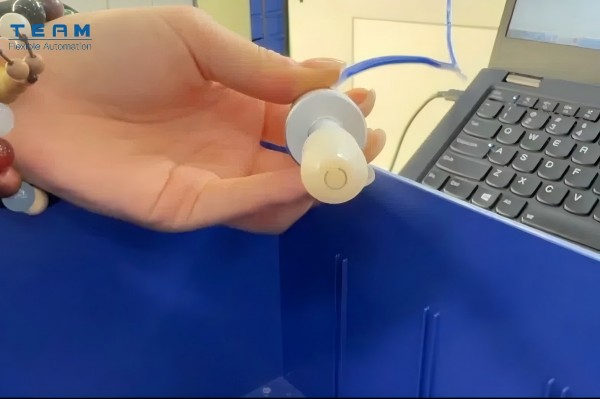

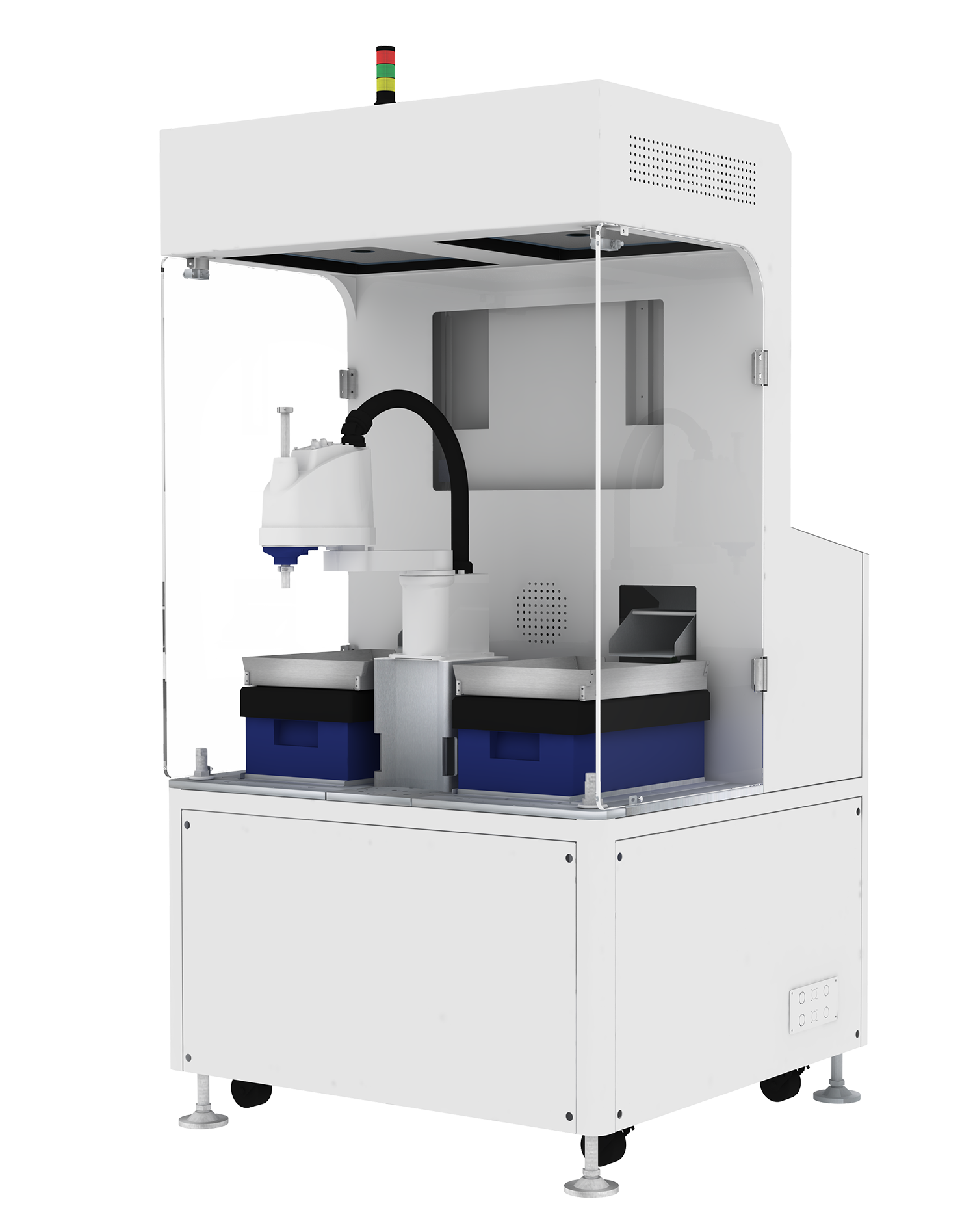

Prototyping for Precision

To achieve better feeding solutions, we’ve incorporated a 3D printer to create prototype plates, suction nozzles, and other custom components for testing. Consider a small, lightweight semi-arc iron ring. Though seemingly standard, its high precision requirements demand a tailored suction nozzle. A nozzle with a too-large port risks air leakage and dropped components, while one with a too-small port can lead to clogging. Only by ensuring the nozzle’s dimensions are precisely aligned with the material can accurate feeding be achieved.

Material Variations Require Verification

Even materials of the same type can behave differently due to variations in weight, material composition, inertia, tolerances, friction, or static electricity. Testing each component is crucial to identifying potential risks early and minimizing downstream disruptions.

Conclusion

Experience is a useful reference, expanding the range of possible feeding strategies and aiding in selecting suitable approaches. However, only actual testing can validate these ideas and prove their feasibility. As the saying goes in the automation industry, experience is a guide, but without testing, there’s no authority to speak.

Home

Home Products

Products Telephone

Telephone Message

Message