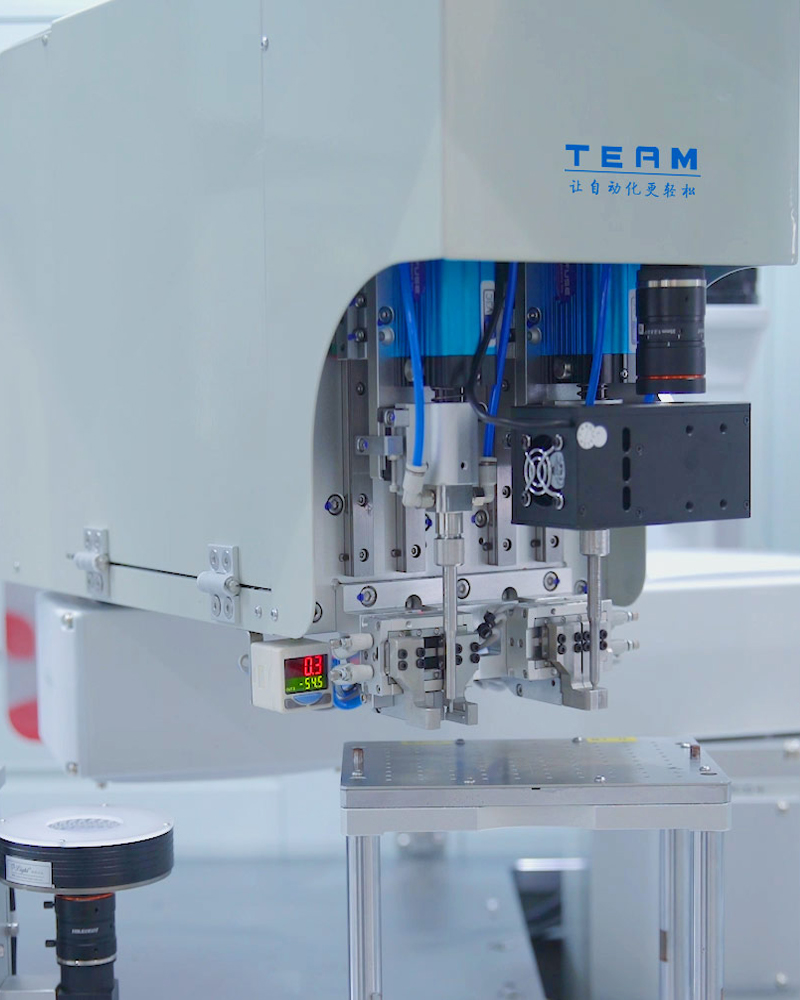

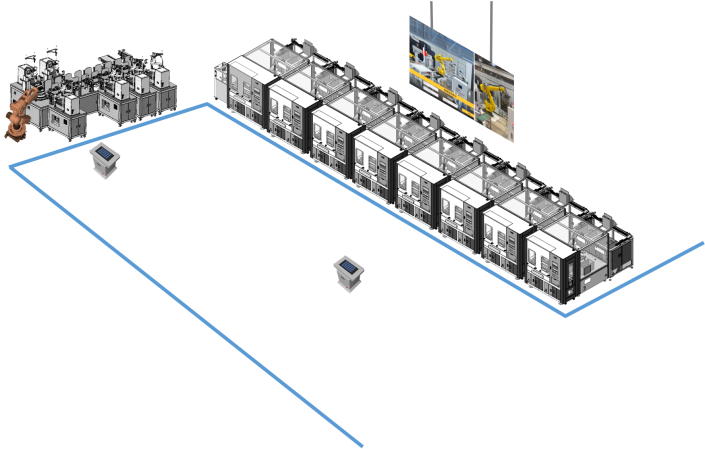

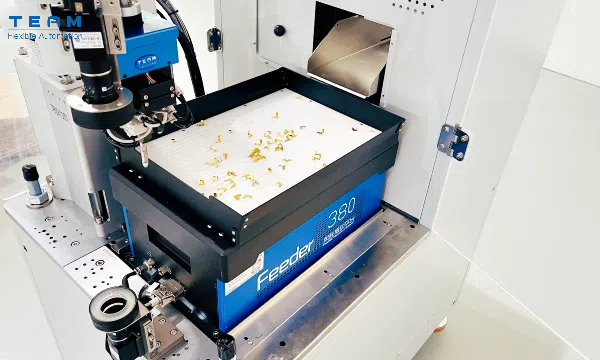

Standardization

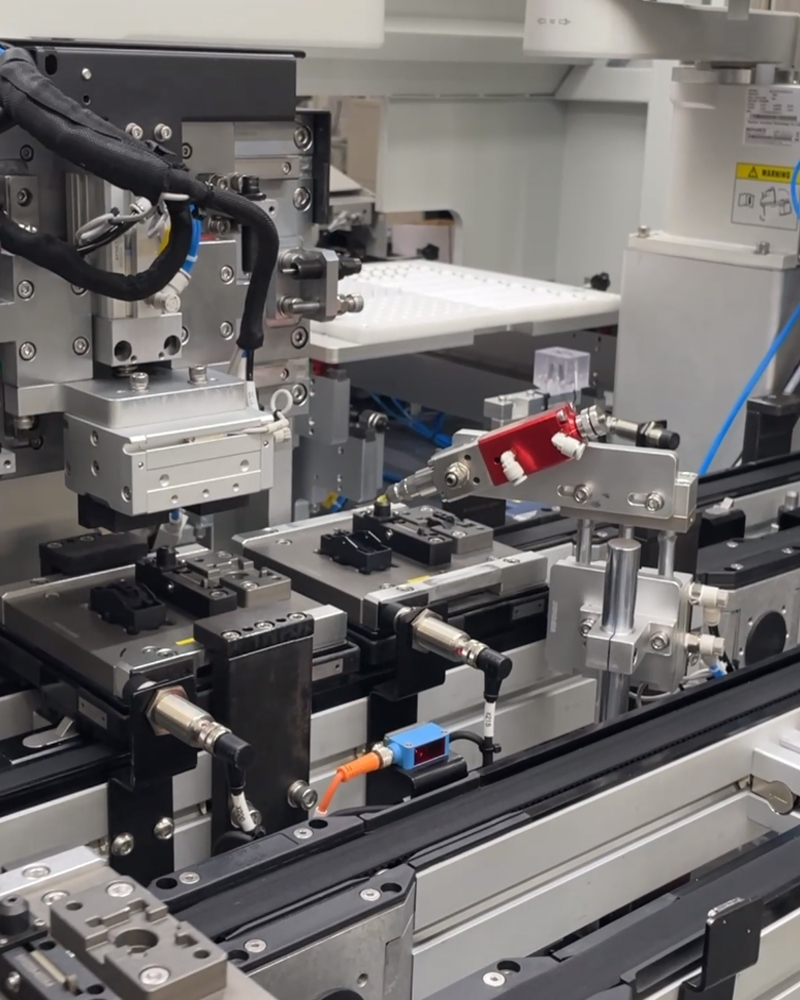

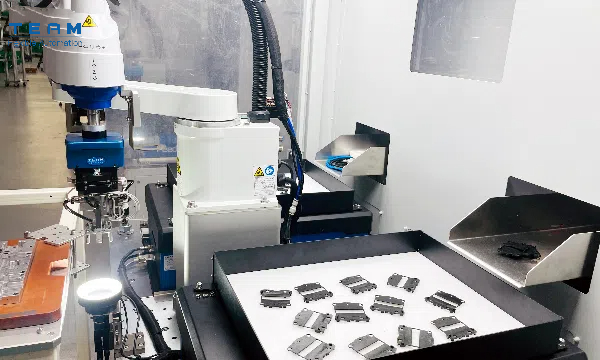

Since its inception, it has accumulated a wealth of standardized hardware modules and is constantly in the process of precipitation. In order to reduce the defects of instability, slow delivery and low reuse rate caused by too many non-standard designs.

Home

Home Products

Products Telephone

Telephone Message

Message