Over the past two decades, China’s industrial automation sector has evolved rapidly. Traditional manual feeding methods have been gradually replaced by machines, leading to innovations like bowl feeders, roller feeders, and flexible feeders.

How Traditional Feeders Work

Traditional circular or roller feeders rely on pulsed electromagnets to generate vertical vibrations. This motion propels parts upward along spiral tracks until they reach the next processing stage.

However, these systems exert significant inertial or impact forces on parts, often causing surface scratches or deformation. They are only suitable for standardized, durable components with simple shapes and high-volume production.

For precision components like FPC flexible circuit boards or delicate electronics, even minor contact during feeding can compromise quality and accuracy. This limitation has driven demand for low-damage flexible feeders.

Why Flexible Feeders Reduce Surface Damage

1. Triaxial Vibration Technology Minimizes Friction

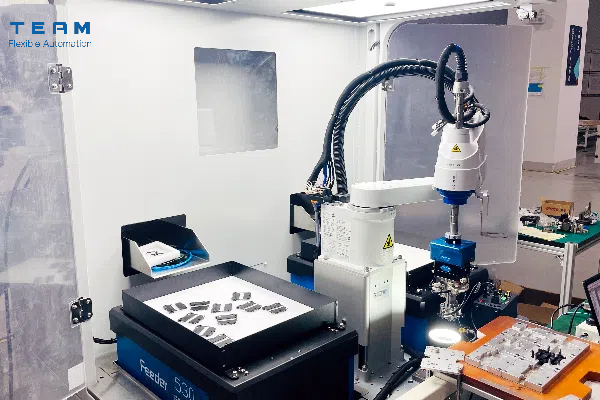

Flexible feeders use triaxial vibration (X/Y/Z axes) based on resonance and coherent wave interference. By adjusting amplitude and frequency, parts are gently guided into position without prolonged vibration cycles. This precision reduces surface wear caused by collisions.

2. Customizable Settings for Part Dimensions

These feeders adapt to part size, shape, and weight by fine-tuning vibration parameters. This ensures controlled forces during movement, achieving optimal part orientation while minimizing scratches.

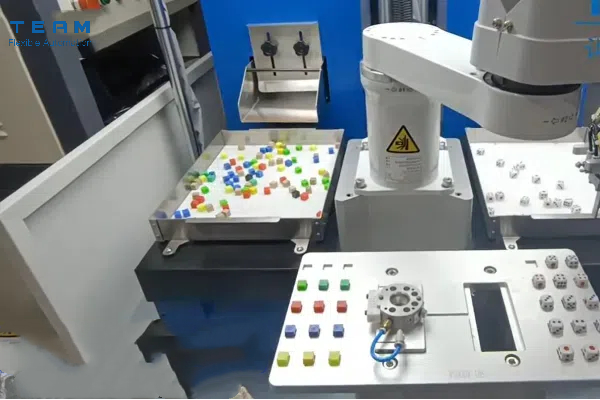

3. Robotic Arm Integration Reduces Contact

Flexible systems often pair with vision-guided robotic arms for pick-and-place operations. After vibration alignment, robotic grippers or suction tools handle parts directly, eliminating sustained friction from traditional feeding methods.

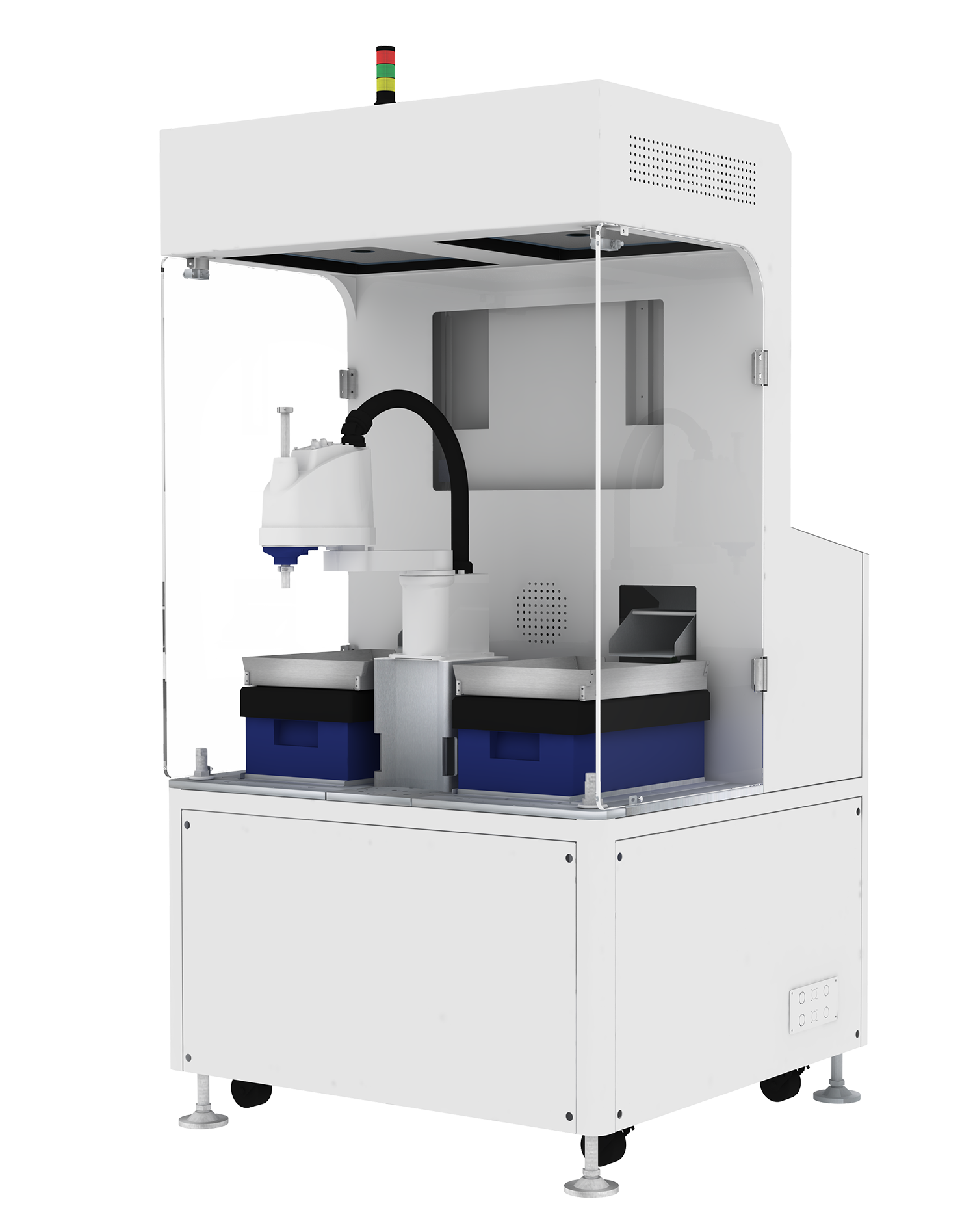

Key Advantages of Flexible Feeders

Low Wear: Ideal for fragile, thin, or irregularly shaped components.

Jam-Free: Ensures smooth material flow even with complex geometries.

High Compatibility: Adapts to diverse part types without retooling.

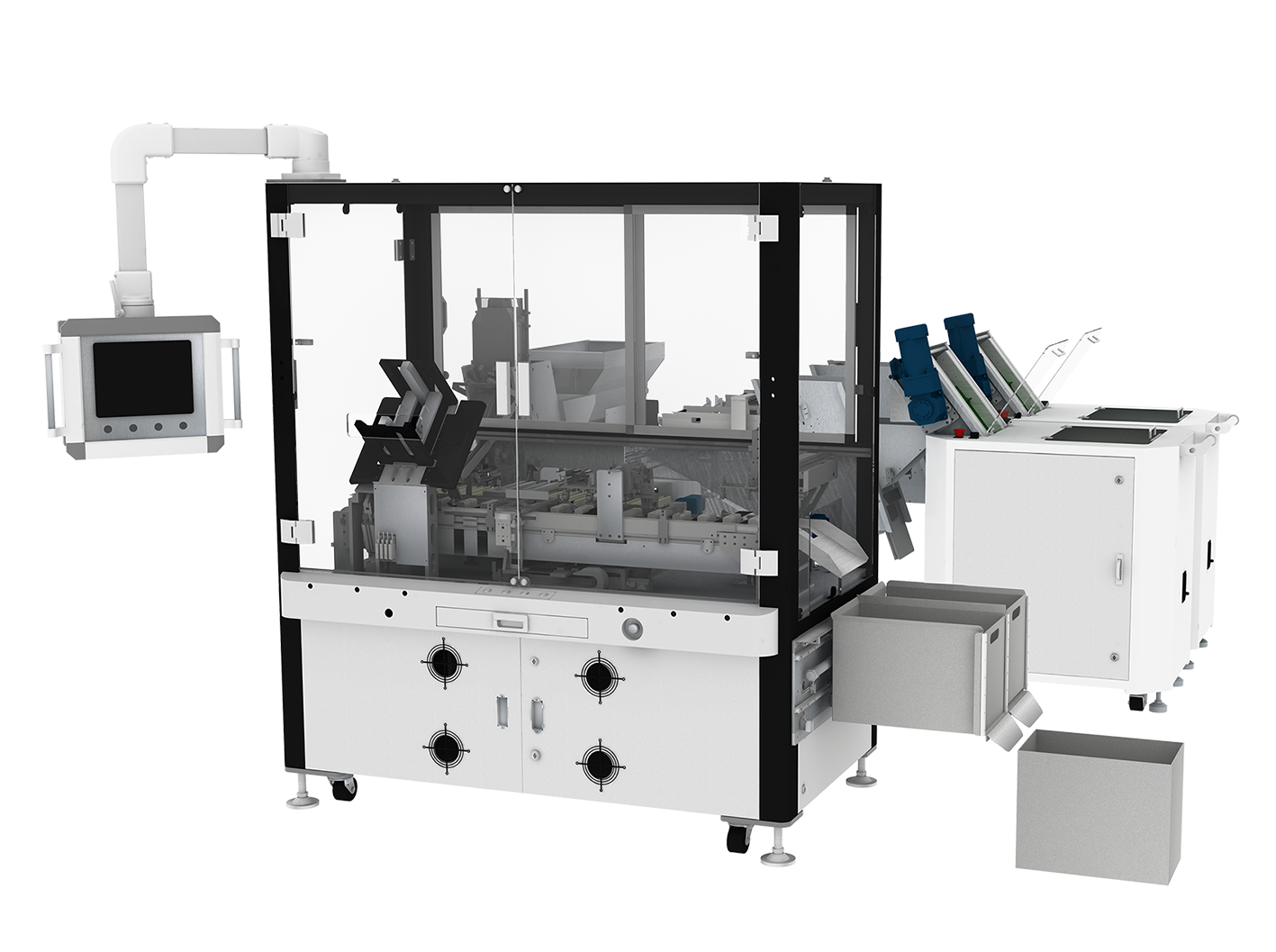

The Evolution from Traditional to Flexible Feeders

Traditional feeders struggled with small, irregular parts—a problem that sparked the invention of flexible vibratory feeders. While this breakthrough emerged from a researcher’s insight, it reflects the inevitable progression of automation technology.

As automation advances, newer technologies may eventually surpass flexible feeders. Yet the pursuit of optimal solutions—higher precision, lower costs, and smarter adaptability—will continue driving innovation in industrial automation.

Home

Home Products

Products Telephone

Telephone Message

Message