If you’ve ever consulted on automation equipment, you may have noticed something surprising: for similar functionality, one supplier may quote a few hundred thousand, while another might quote in the millions. Are the low-end quotes unsustainable, or are the high-end options overpriced? Reducing the entire automation market to "you get what you pay for" is overly simplistic. Let’s explore the factors that contribute to these wide pricing variations in automation equipment.

1. Differences in Hardware Costs

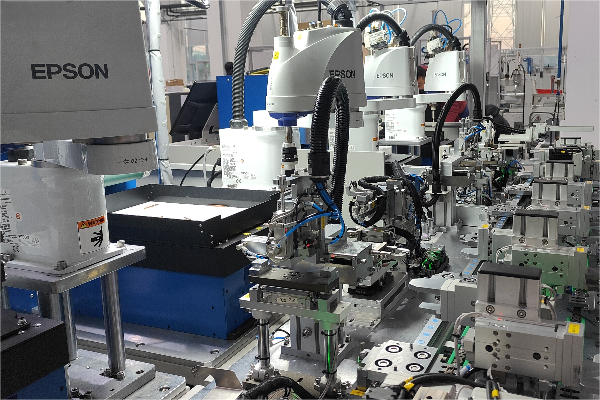

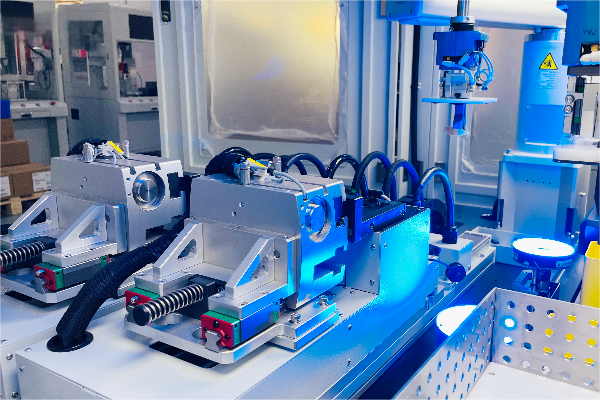

Hardware cost is the most obvious and significant difference. From the choice between modules and robotic arms to selecting domestic versus global brands, the components used heavily impact the price. Camera specifications, the number of lenses, electrical component brands—each choice, tailored to different operational requirements and environments, can lead to substantial cost differences.

2. The Cost-Benefit Balance in System Design

While hardware is a core cost, manufacturers primarily focus on balancing both long-term and short-term cost factors:

Long-term Cost: This involves not just the initial expense but the overall lifecycle costs, such as adaptability, fault tolerance, and potential future modifications. Investing in high-quality, stable hardware often reduces long-term costs.

Short-term Cost: Short-term considerations are about immediate production requirements and product lifecycle. For rapidly changing products, using more affordable, lower redundancy hardware can make sense, reducing short-term investment.

Fixed Cost vs. Time Cost: Projects with tighter deadlines generally incur higher costs, and the trade-offs between equipment and production costs mean that in some cases, the equipment might exceed the product's profitability, extending the ROI period.

Ultimately, system design cost reflects a client’s expectations for automation equipment and can result in significant pricing variations. This is why automation providers often seek budget insights upfront.

3. Variations in After-Sales Support Costs

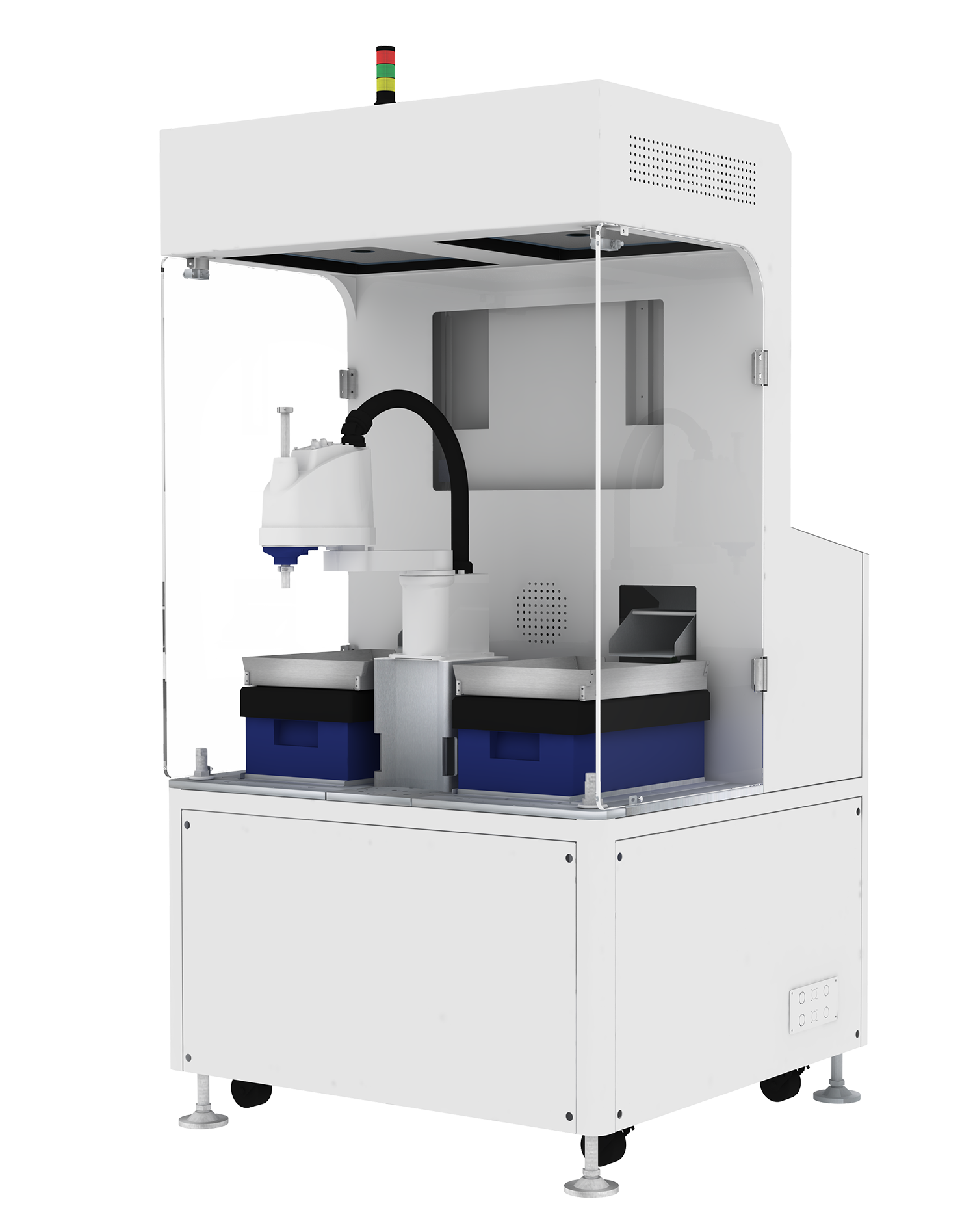

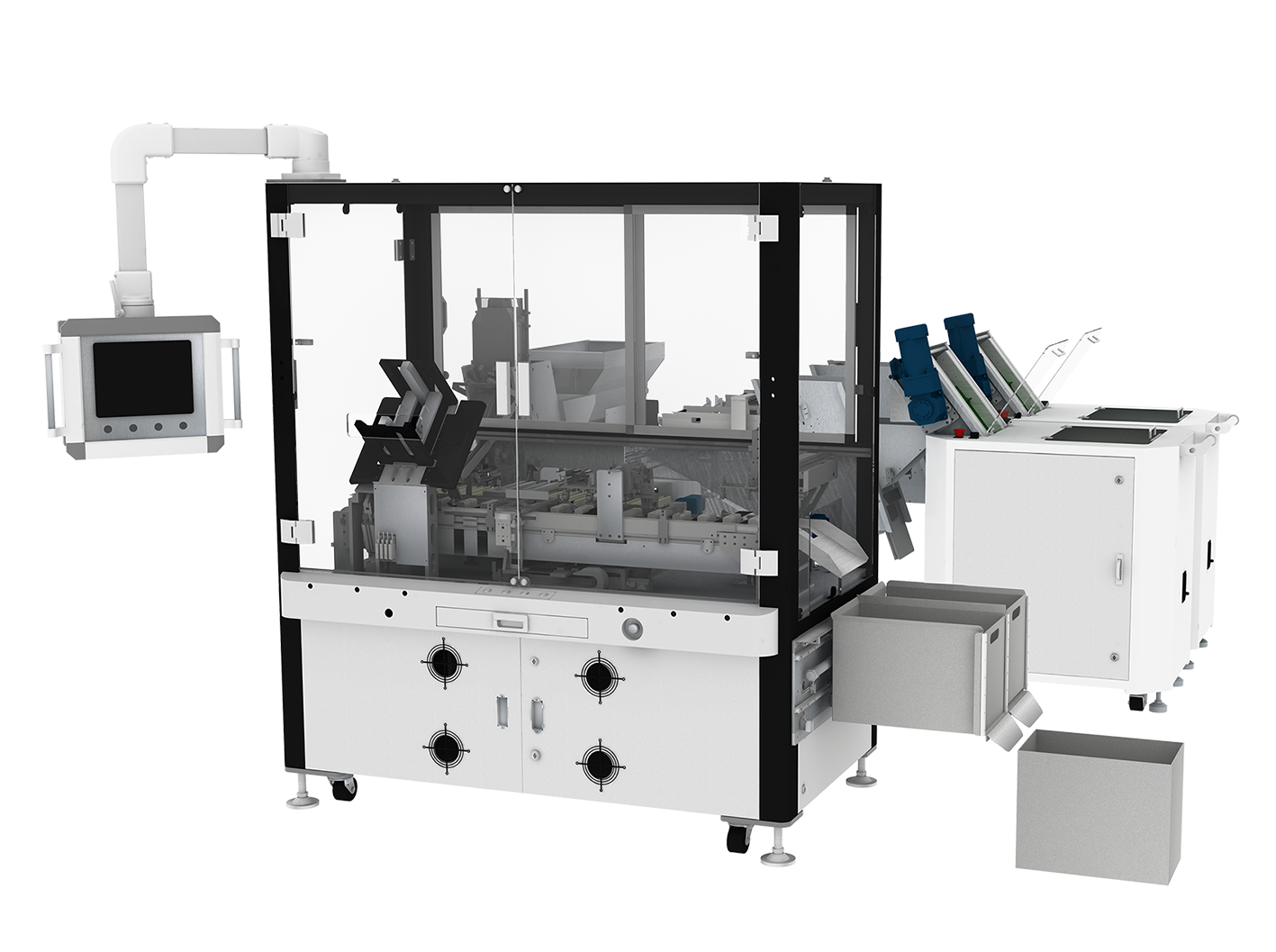

After-sales costs depend largely on labor and travel expenses, and the level of service directly influences the equipment’s final price. Using flexible feeding equipment as an example, here are three typical service delivery models:

Factory Acceptance: This mode involves minimal support. The supplier assembles the equipment per the specifications, the client performs an in-factory acceptance test, and after delivery, any necessary adjustments are the client’s responsibility. This "DIY" style is best for companies with some in-house automation expertise.

Limited On-Site Service: This model includes initial on-site setup and testing, but any post-installation issues require additional service fees.

Turnkey Solution: This offers comprehensive after-sales support, with an agreed service period where any issues are promptly resolved on-site. This model provides the highest assurance and is ideal for those new to automation, provided the budget allows.

Automation equipment prices are a result of hardware, system design, and support labor costs. There’s no "no-cost" discount, nor is there an "added value" surcharge; market dynamics apply here, too.

Conclusion

Just as in buying a computer—whether you choose a simple office laptop or a high-performance, liquid-cooled gaming rig, whether you prefer an all-in-one setup or a custom DIY build—it’s all about your specific needs and goals. At the end of the day, the choice reflects your priorities.

Home

Home Products

Products Telephone

Telephone Message

Message