The Live (L) and Neutral (N) terminal, or LN terminal, is a critical component in electric sockets, serving as the conductive link between the neutral and live wires. However, automating the feeding of this small LN terminal has long been a challenge in the electric socket industry.

LN terminals are irregularly shaped, which poses problems for traditional bowl feeders, leading to issues such as material jams and wear. Additionally, different specifications of LN terminals require custom vibration feeders, which lack compatibility across different models.

Through collaboration with relevant enterprises, we successfully developed a flexible assembly solution for the LN terminal in electric sockets, solving this industry problem and replicating it stably across multiple production lines.

1. Solution Overview

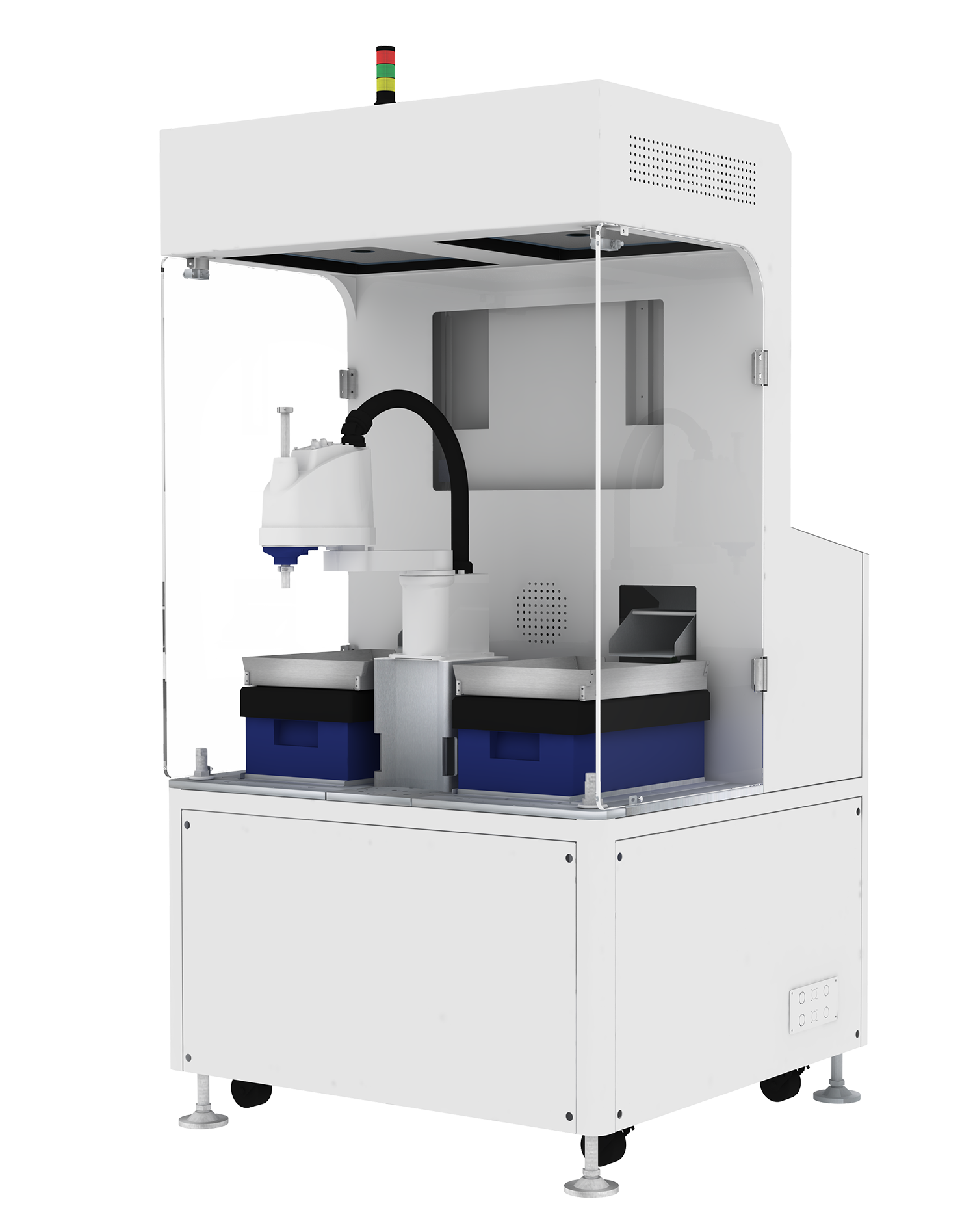

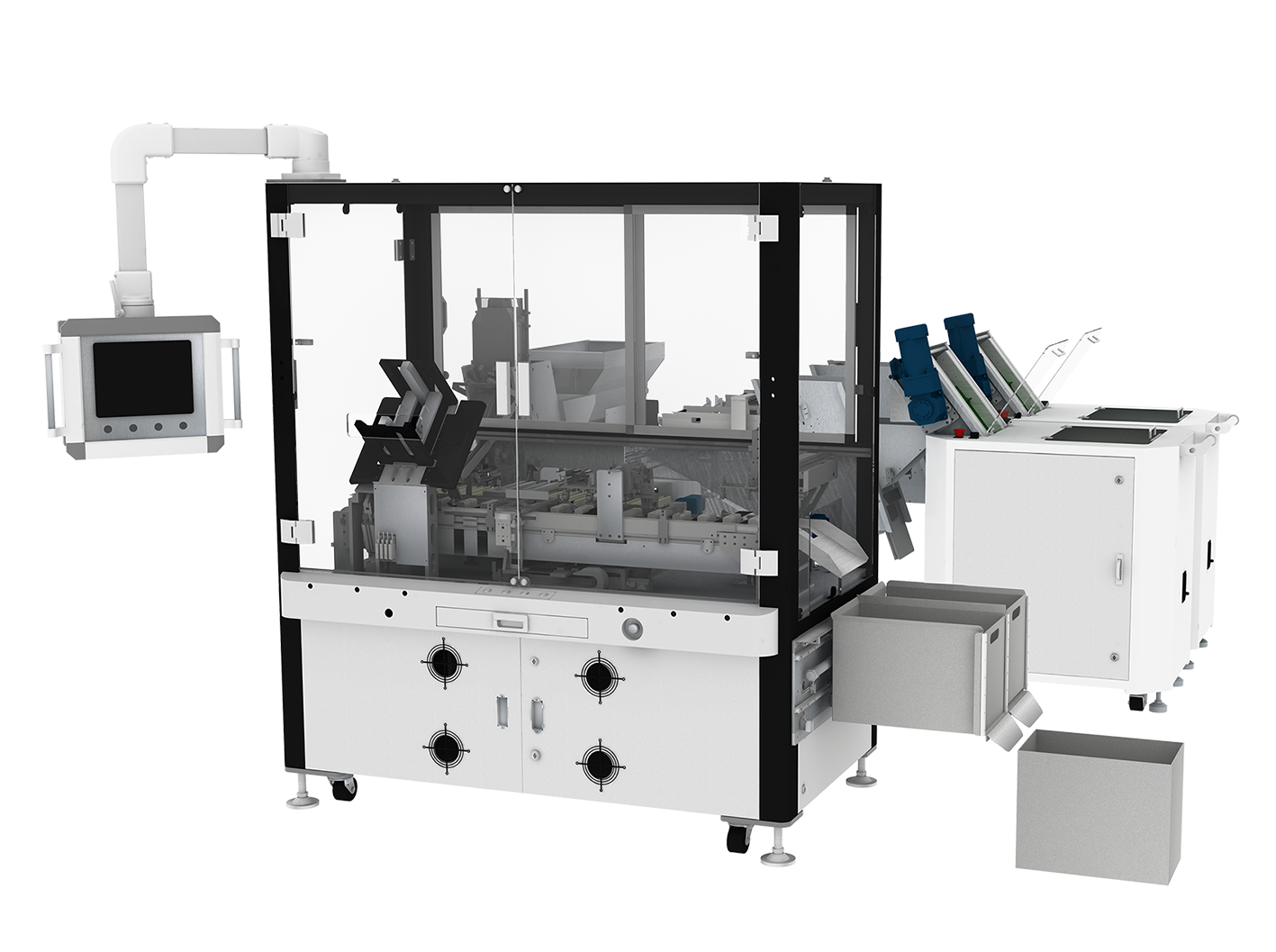

This solution is a typical flexible automation standard system consisting of a step feeder, flexible feeder, manipulator, and a vision inspection system. The main steps are: loading the socket base plate, assembling the LN terminal irregular-shaped component using a manipulator, and then inspecting the product for quality.

Here’s a detailed breakdown of each step:

1.1 Socket Panel Feeding

The socket panel are square, molded parts that require a specific orientation during assembly with the back of the panel facing upwards. Therefore, a large-capacity belt conveyor and step feeder system were chosen for this task. A vision detection system and air blowing mechanism are integrated at the top of the step feeder to blow misoriented panels back onto the conveyor and adjust their angle to ensure proper orientation for feeding.

1.2 LN Terminal Irregular-Shaped Component Feeding

LN terminals come in a variety of shapes, so to avoid material piling, additional buffering space is provided by a dual-level feeder system. Since the LN terminal is irregularly shaped, traditional feeding methods are not suitable. Instead, a "one-to-two" flexible feeder workstation is used to vibrate mixed LN terminals into an ideal position for manipulator to pick up. The manipulators, guided by a vision system, accurately pick and place the components into a buffer system, awaiting the next step in assembly.

1.3 LN Terminal Installation and Inspection

Once the socket panels are fed with proper orientation, they are transferred to the LN terminal installation section, where the LN terminals are ready in the buffer platform. The manipulator, with vision assistance, picks and installs the LN terminal onto the socket panel. After assembly, the product undergoes vision inspection. Defective products are directed to a reject bin for easy traceability, while the qualified products continue to the next process.

This entire assembly and inspection process is tightly coordinated between the vision system, manipulators, and other mechanisms, benefiting from the innovative design of the layout, material handling, and buffering system. The solution has been refined through numerous iterations, resulting in a mature, stable system.

2. Solution Highlights

2.1 Strong Compatibility

The use of flexible feeder, quick-change fixtures, modular tooling, and high-precision vision systems allows the equipment to accommodate various product specifications, saving costs and eliminating the need for repeated investments.

2.2 Rapid Changeover

All equipment is designed with standard modular components that enable fast changeover by replacing fixtures and tooling, facilitating quick production line adjustments.

2.3 Quality Inspection

Each carrier is equipped with a sensor chip to track its position during operation. In the event of an issue within the automated process, the system can quickly pinpoint the source of the problem, enabling real-time quality management.

3. Conclusion

This solution effectively addresses the challenges of feeding irregular-shaped LN terminals by using flexible feeding systems. It can accommodate various socket panel assembly specifications and quickly adapt to changes in product designs to meet market demands, offering high compatibility and flexibility while reducing the need for repetitive investments. The solution has been thoroughly tested and adjusted through multiple iterations, making it stable and ready for quick deployment. Additionally, features such as the air-blown reject system, LN terminal rotating buffer, quick-change fixtures, and carrier tracking all help enterprises move closer to achieving full automation and smart manufacturing.

Home

Home Products

Products Telephone

Telephone Message

Message